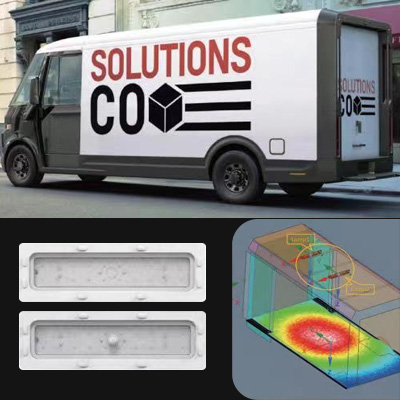

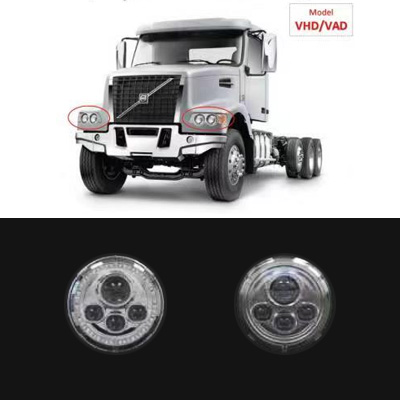

Aluminum die-casting & surface treatment | High-quality and cost-saving integrated molding solution

From precision casting to surface treatment that combines aesthetics and functionality, it provides an integrated service

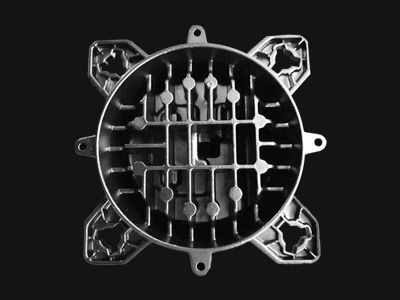

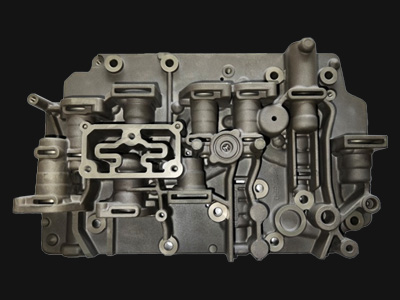

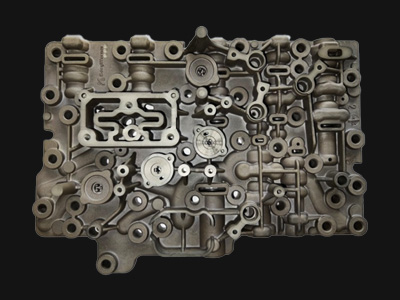

The core of casting technology:

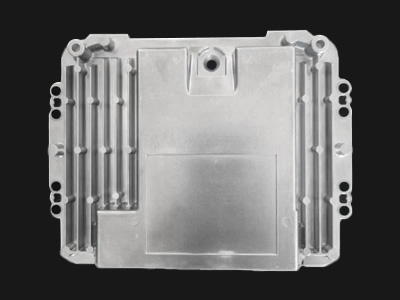

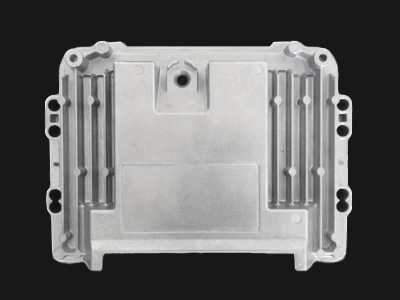

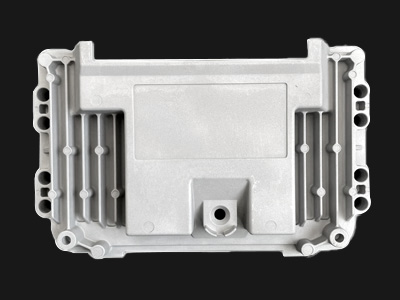

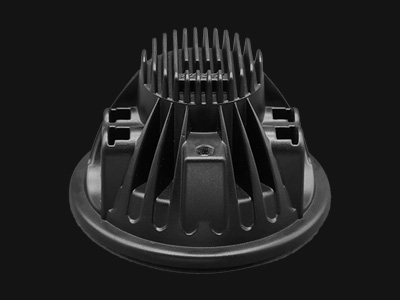

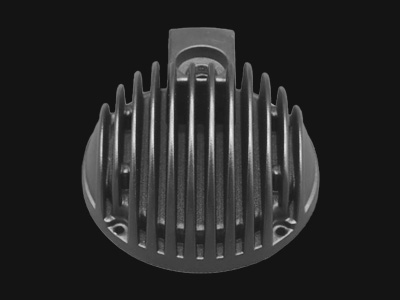

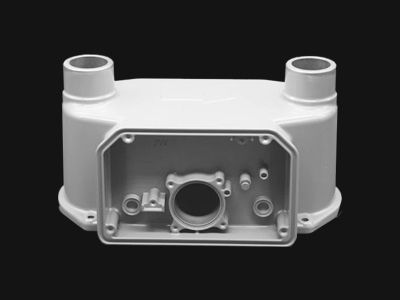

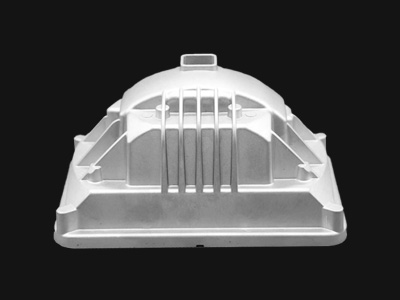

With the latest casting machine group that supports 250 to 1000 tons of injection pressure, parts with complex shapes and thin walls (minimum wall thickness 0.8 mm) are molded with high precision.

Casting features:

Material: JIS H5302 ADC12 / A380 compatible.

Dimensional accuracy: CT6 grade (ISO 8062 compliant)

Production capacity: 3 million shots per month (mass production optimization with multiple molds).

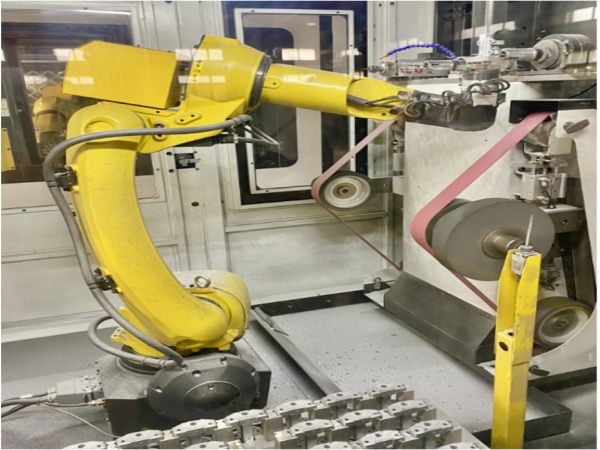

Post-process cooperation: Seamless connection with CNC secondary processing and polishing.

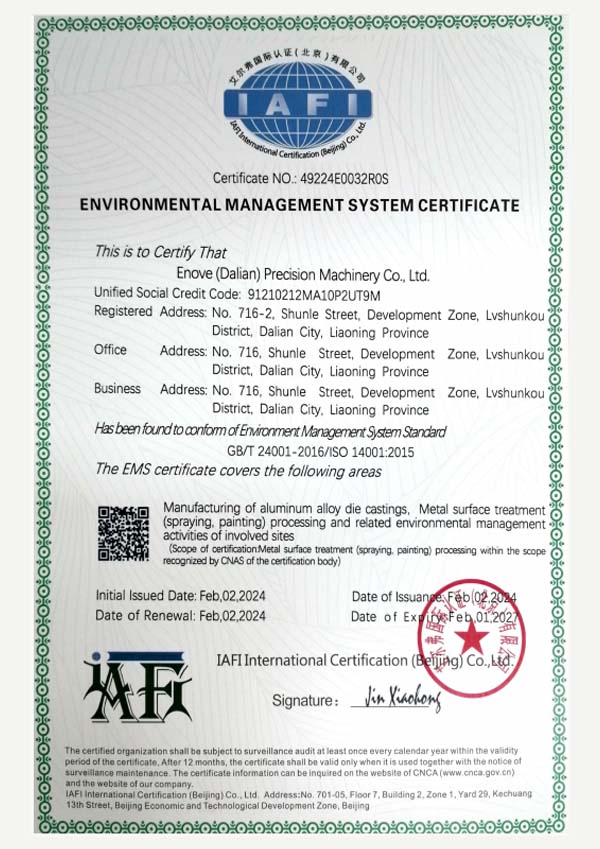

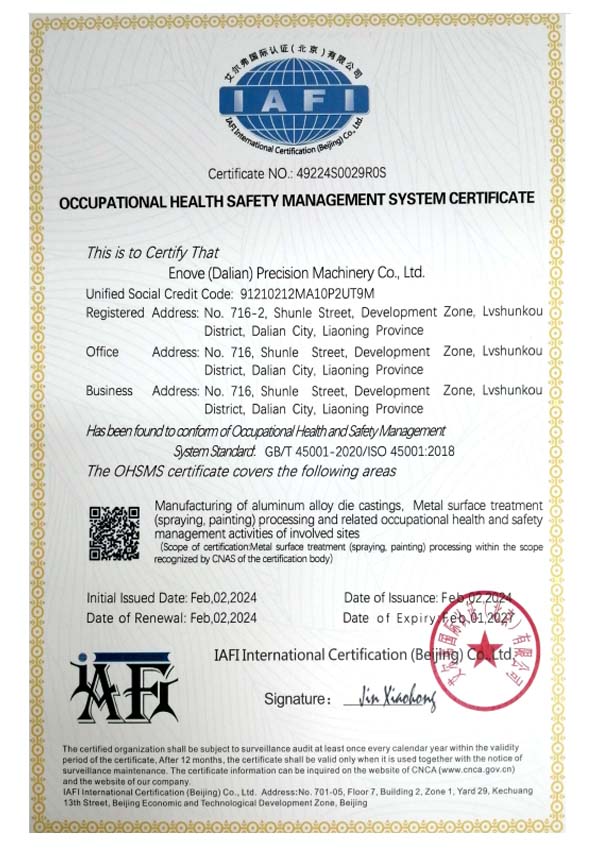

Acquired ISO 14001/45001 certification.

Acquired IATF 16949 certification.

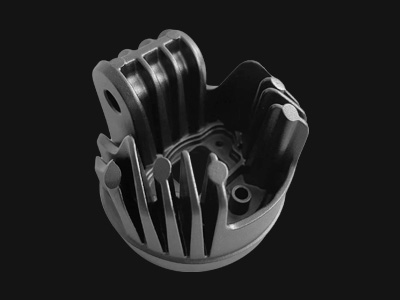

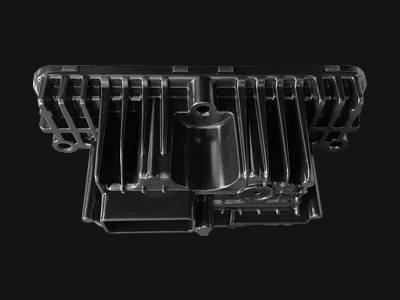

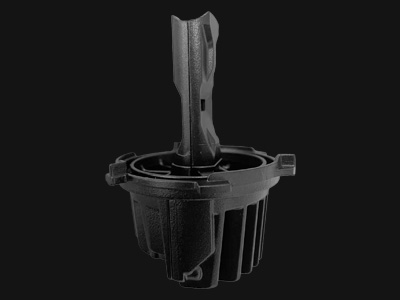

Example: Automobile ECU housing (0.05mm tolerance) / Drone motor housing

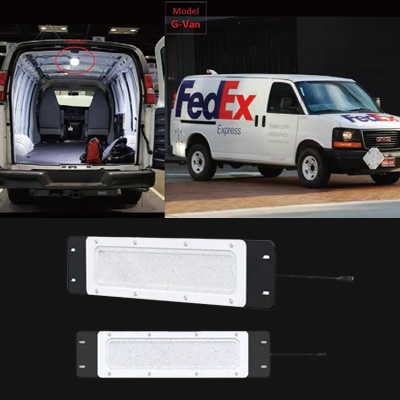

Surface treatment technology system:

Weather resistance: JIS K 5600 compliant 2000 hours sun test support.

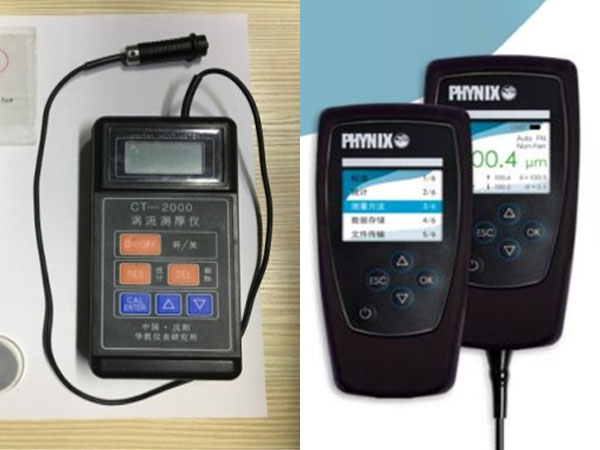

Film thickness control: 40 to 120μm (electrostatic spray + UV curing).

Color: Mansell color book standard 200 colors (metal tone, light-out finish possible).

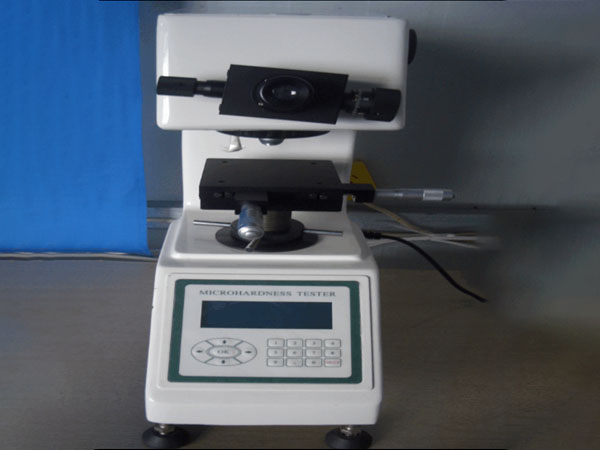

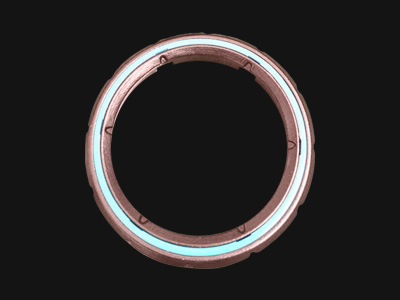

Film thickness: 5 to 25μm (hard anodizing: HV400 achieved)

Corrosion Resistance: JIS H 8601 Class C (1000 Hours Salt Spray Test)

Special functions: Conductive treatment/antibacterial coating compatible

Nickel electroless plating (uniform adhesion)

Trivalent chromate (environmentally compatible)

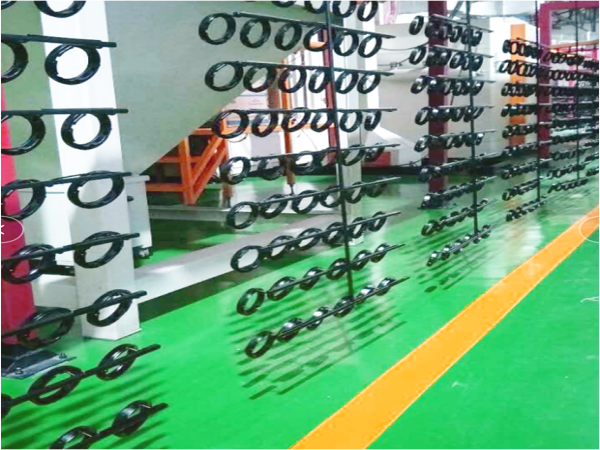

Electrode ding Painting line

Three-dimensional measuring machine

Surface roughness measuring machine

Sample polishing equipment