"Precision casting" technology that realizes high precision and complex shapes

Precision casting is a manufacturing process that has advanced traditional techniques, also known as the lost wax method. Its biggest feature is that it can produce metal parts with extremely complex shapes, which are difficult for other processing methods, high dimensional accuracy, and excellent surface quality by integral molding.

Norui's precision casting process:

Precision wax model creation: Based on design data, we create a high-precision wax (wax) model. It is also possible to mold multiple parts in one piece.

Mold (shell mold) formation: Mold (shell mold) formation:

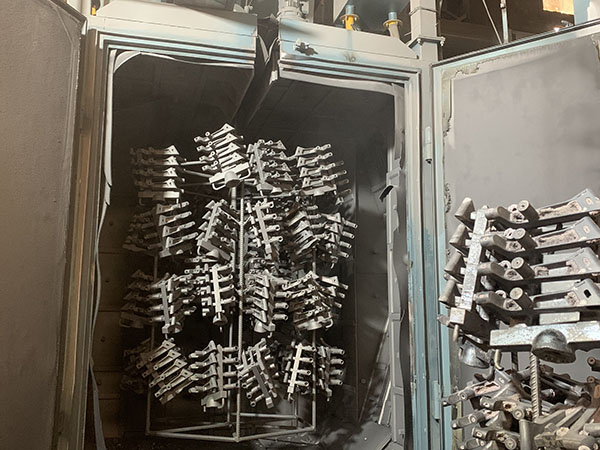

Dewaxing and firing: Melt the wax inside the mold (dewaxing) and harden it at a high temperature.

Hot water casting: Various metals (stainless steel, alloy steel, superalloy, kovar alloy, aluminum alloy, copper alloy, etc.) are melted according to customer requirements and poured into a high-precision mold.。

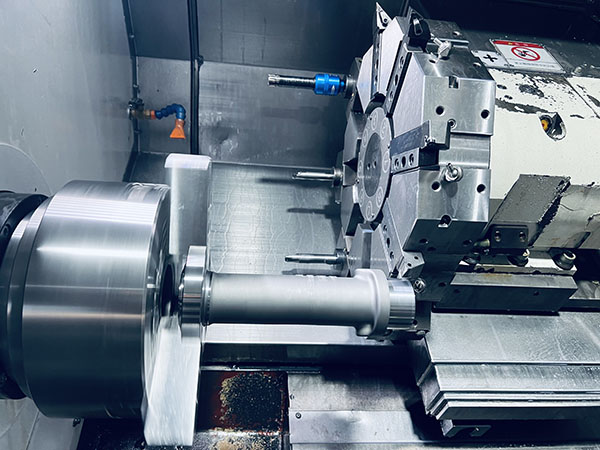

Mold removal and finishing: After solidification, remove the mold and cut the gate (hot water mouth). If necessary, secondary processing such as heat treatment, polishing, machining, and surface treatment are applied to complete the final product.

Strengths of Nuorui Precision Casting Technology:

Excellent dimensional accuracy and reproducibility: It achieves a high dimensional accuracy of about ±0.1mm to ±0.5mm, minimizing variations between lots.

Outstanding surface finish: The cast skin is very smooth, which can significantly reduce the polishing and processing of the post-process.

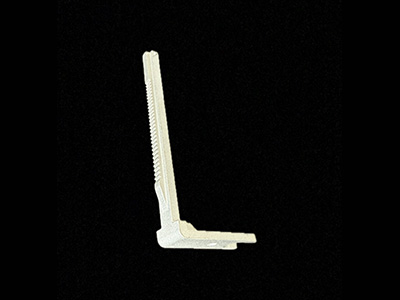

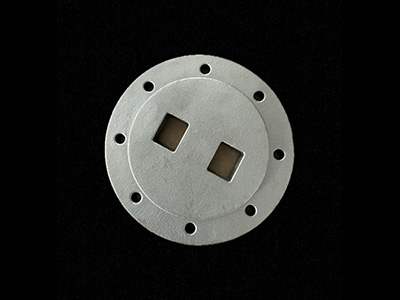

Realization of complex and integrated shapes: Since there is no need for a pull-out slope, or it is only very small, it is possible to mold hollow structures, internal complex shapes, thin-walled parts, etc.

Compatible with a wide range of materials: Compatible with a variety of metal materials, you can choose the best materials for your application, such as heat resistance, corrosion resistance, and strength.

Cost efficiency (especially complex shapes): For parts with particularly complex shapes, there is less material loss compared to cutting, etc., which leads to overall cost reduction.

Strict quality control: We carry out strict quality inspection at each stage of the process to ensure that we meet the customer's required specifications and high reliability.

Main products and application fields:

Product examples: valve parts, pump housings, turbine blades, nozzles, gear cases, hydraulic and pneumatic parts, food machinery parts, semiconductor equipment parts, medical device parts, etc.

Application fields: Automobiles and transportation equipment, industrial machinery and equipment, aerospace (commosity products), energy (oil and gas), food processing machinery, semiconductor manufacturing equipment, medical equipment, water treatment equipment, etc.。

Dalian Nuorui Precision Metal Technology aims to be a reliable bridge between customers and excellent manufacturers in the procurement of precision casting parts. As a partner who realizes high quality, reasonable price, and stable supply, we will contribute to the success of our customers' businesses.。

Light-emitting spectral analyzer

7.Foundry dismantling work

12.Dimensional inspection