- HOME

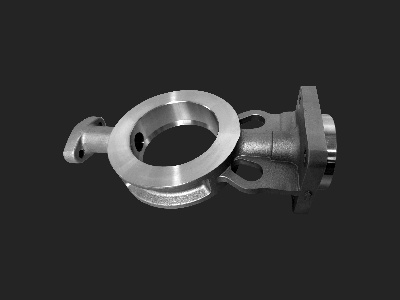

- Lost wax (precision casting) Lost wax (precision casting) Lost wax (precision casting)

- Die casting & painting Die casting & painting Die casting & painting

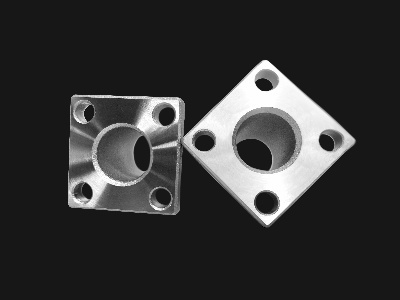

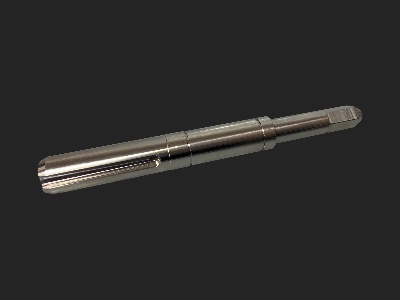

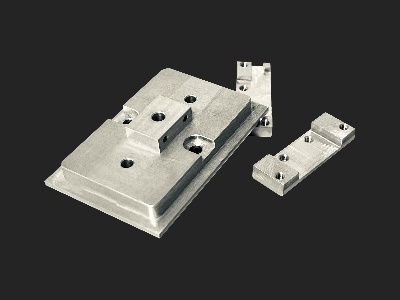

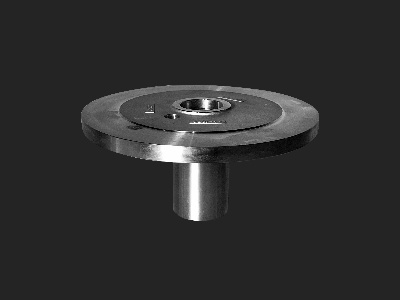

- Machining Machining Machining

- Sheet metal &deep drawing &stamping processing Sheet metal &deep drawing &stamping processing Sheet metal &deep drawing &stamping processing

- COMPANY PROFILE