- HOME

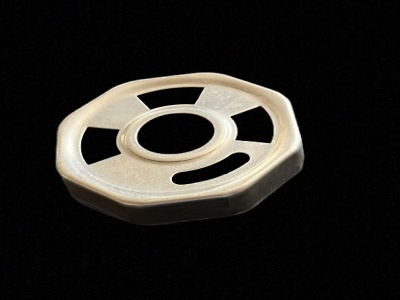

- Lost wax (precision casting) Lost wax (precision casting) Lost wax (precision casting)

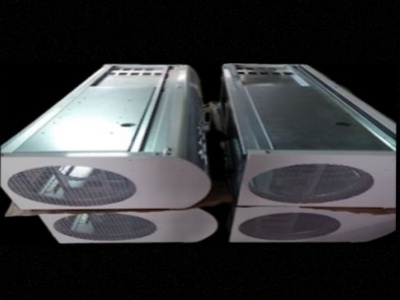

- Die casting & painting Die casting & painting Die casting & painting

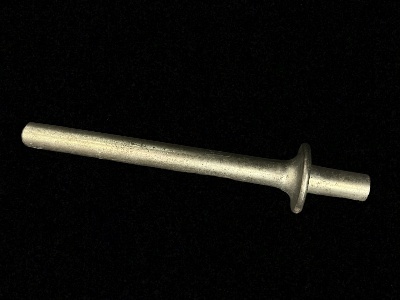

- Machining Machining Machining

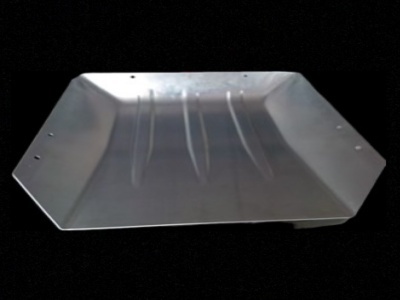

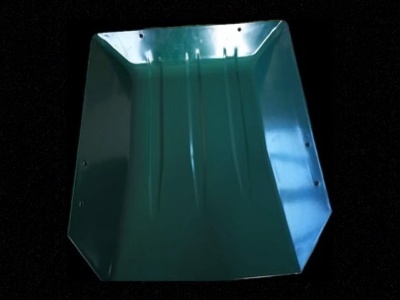

- Sheet metal &deep drawing &stamping processing Sheet metal &deep drawing &stamping processing Sheet metal &deep drawing &stamping processing

- COMPANY PROFILE